Revolutionizing Railway Signaling through BIM

A precise design is required to run a highly secure and dependable signaling system like ETCS with Automatic Train Operation (ATO). All assets must be installed with a very minimal installation tolerance.

Traditional way

There are well-defined methods for installation activities along the rail track, which are based on rules and norms. Many of these jobs are traditionally paper-based — such as filling out spreadsheets and forms — necessitating a second activity of moving the input data into another system.

When installing and maintaining the track, the installation and maintenance crews rely on having the proper information on hand. To guarantee that all essential data required for optimal execution is obtained, storing data in many systems necessitates a high degree of organization. Collecting all pertinent information takes longer when information is stored in several systems.

The enormous distances between the office and the work location, as well as operating in places without a “net connection,” make information transfer complicated and sluggish. The traditional way to reporting is to work on-site for a week and then begin official reporting the following week when everyone is back in the office.

As a result, the findings — and perhaps the notification that some assets could not be installed due to collisions — are available a few days later in the design office. After that, the design, engineering, and installation cycle begin again.

A new dawn with BIM

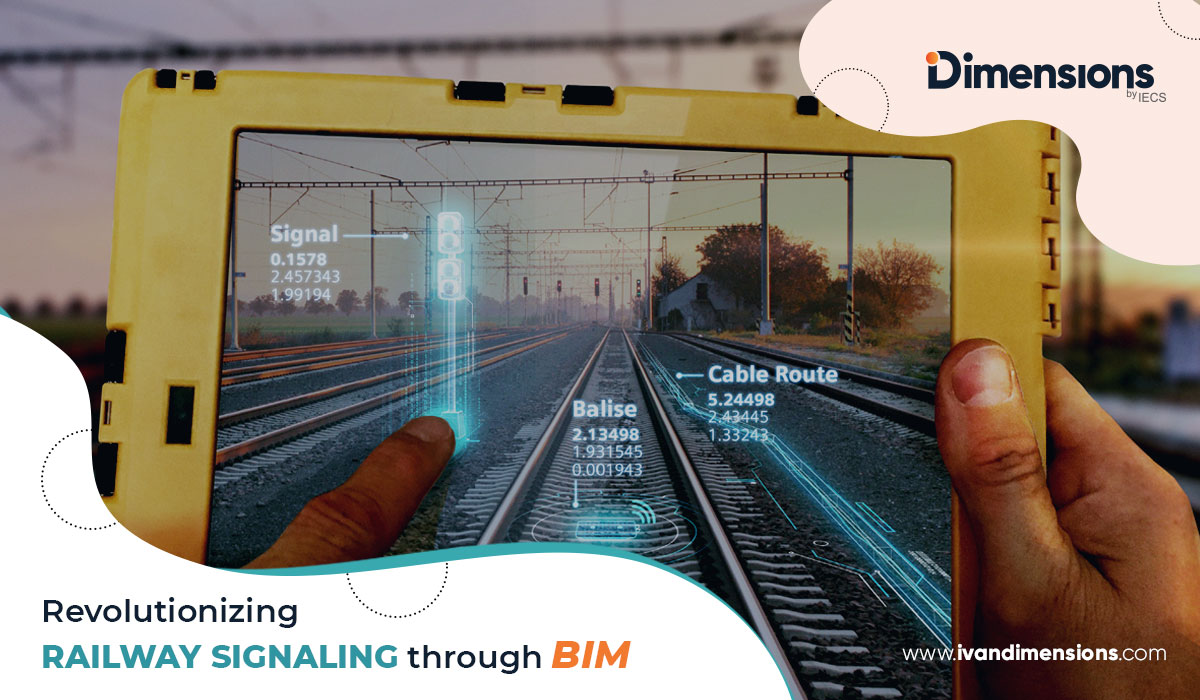

Thus, to address the lacunae with the existing way of working it is important to use technology. The two prominent technology used in this case was laser scanning and 3D visualization services. First, the 3D model of the railway track would be created using BIM while integrating the geological data from satellite coordinates. The 3D visualization services offered by a leading BIM provider with the help of BIM can help to visualize the accuracy of the model and its placement on site.

With the 3D model of the tracks offered through 3D visualization services, it is possible to ensure that the model is per the client’s requirements and is adhering to the required safety protocols.

Point cloud services will help to monitor ongoing construction and ensure adherence of the construction with the model. In this respect, the point cloud services provider uses a laser scanner to create a point cloud image of the construction. The same point cloud image is converted into a 3D model through BIM software.

By comparing the 3D model generated through point cloud with the original model created through BIM, it is possible to verify construction progress and track the accuracy of the construction. Thus, BIM has the potential to revolutionize the construction and installation of railway signaling mechanisms.

However, the application of BIM does not end here. As a revolutionary technology, the application of BIM can offer several benefits to the construction industry as a whole. From reducing coordination issues to ensuring fast construction; BIM offers a plethora of benefits. It can also help monitor the entire construction activity and ensure that there are no bottlenecks. It can also offer accurate material and cost estimation for the project.

Comments

Post a Comment